Description

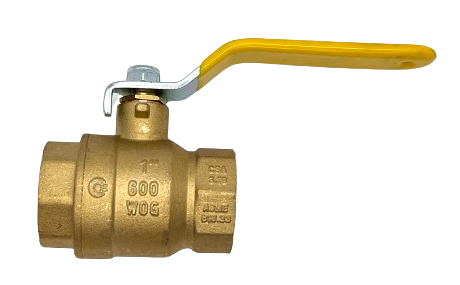

Full Port Ball Valves are special types of valves used in plumbing systems to control the flow of water or other fluids. The unique design of these valves allows for maximum flow because the opening inside the valve is the same size as the pipe. This means that Full Port Ball Valves reduce pressure loss and allow for smooth, unrestricted water flow, making them a preferred choice in many plumbing and industrial applications.

How to Operate Full Port Ball Valves

Full Port Ball Valves is how easy they are to operate. With just a quarter turn of the handle, you can completely open or close the valve, giving you full control over the water flow. Full Port Ball Valves is ideal for areas where you need to shut off or regulate water quickly, such as in kitchens, bathrooms, or heating systems.

The durability of Full Port Ball Valves

Full Port Ball Valves are also very durable and long-lasting. They are often made from strong materials like brass or stainless steel, which makes them resistant to corrosion and wear.

At eff-fitting.ca we offer a wide selection of full Port Ball Valves in different sizes to suit your needs. Our valves are easy to install, even for beginners, and provide a reliable solution for controlling water flow.